MORE THAN JUST RUBBER

Delmon Group, rubber supplier

Delmon Group is a rubber supplier for antivibration and sealing solutions.

Its know-how includes: FORMULATION of rubber, expertise of BONDING, RUBBER MOLDING, HIGH-TEMPERATURE SILICONE.

KEY FIGURES

SINCE

1966

TURNOVER

60 M

COUNTRIES

4

PLANTS

4

EMPLOYEES

450

PRESSES

120

RUBBER SOLUTIONS

SINCE 1986 DELMON GROUP HAS BEEN DEVELOPING COMPLETE SOLUTIONS IN PROXIMITY WITH AEROSPACE MANUFACTURERS, ENGINE MANUFACTURERS AND EQUIPMENT SUPPLIERS.

The development of its elastomer formulas allows to provide a wide range of solutions that meet standard or complex requirements.

Delmon Group is rubber supplier able to provide a wide range of solutions for vibration and thermal insulation, air, fluid and fire sealing, to meet the requirements of NFL 17107, ISO2685, AC20-13…

Delmon group has been a rubber supplier solution to the automotive industry over 50 years.

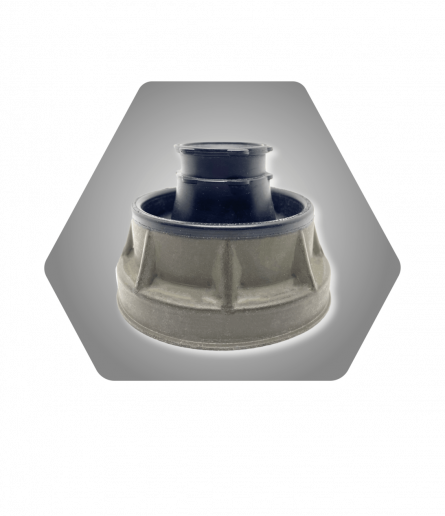

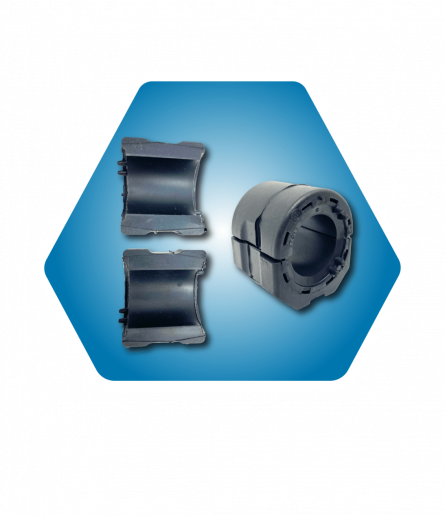

The company manufactures rubber/metal or plastic anti-vibration systems, as well as complex sealing functions using specific elastomer formulas or on demand.

Its capacity for finite element analysis (FEA) allows to anticipate potential problems before validation on a specific test bench.

Present in various industrial sectors, Delmon Group develops complete sealing and antivibration solutions. The perfect knowledge proximity of customer needs allows Delmon Group to offer a wide range of solutions that meet the most complex environments (resistant to wear, abrasion, hydrocarbons …).

As a key player in aerospace and automotive sectors, the company is able to offer you proven solutions used in these sectors.

Delmon Group is a major player in elastomer solutions for this sector and able to propose very specific solutions for this complex environment.

Delmon Group solution’s are designed to meet your specifications thanks to tailor-made proposals using proven materials and technologies.

DEFENSE RUBBER

Delmon Group works in partnership with major manufacturers and tiers 1 in this sector.

The company has been working for years by providing anti vibration solutions for passenger comfort and safety by improving vibration disturbance (metro, tram and train).

Delmon group has been developing tailored solutions in close partnership with the major energy actors since 1971 (renewable, oil and gas).

In this sector, Delmon Group provides a wide range of damping and sealing solutions (air, water, oil, mud, gas), essential to meet NFL 17107 specifications. The company products are dedicated for extreme applications (high pressure: up to at 2000 bar; high temperature: up to 300 ° c ; or extreme weather conditions).

The group is able to design high-performance compounds such as : FKM, FFKM, HNBR …

ENERGY RUBBER

VISION & STRATEGY

TARGETS

Revenue of 100 M€

Globalization

MISSION

Serve better and faster its customers

in expertise fields

VISION

Ensuring sustainable

growth.

VALUES

Agile, Committed, Responsive,

Together-Partner.

Delmon Group develops and manufactures its parts, components and rubber solutions for antivibration and sealing.

The group works for many key sectors such as Automotive, Aerospace, Defense & Industry (Energy, railway, oil exploration).

Delmon Group develops its own rubber recipes, manufactures mixings rubber, designs and tests parts to meet customer’s specifications (standard or specific).

COMMERCIAL AND BUYER FOLDERS

Click here to download commercial and buyer folders !

To obtain the synthetic overview, you must to contact us and mention in the « your request » box, that you want the overview.

FIND DELMON GROUP

Delmon Group has developed its presence to propose global solutions.

The footprint of Delmon Group is 5 plants Worldwide and partnership in USA.

Delmon Group extended abroad its activities with the target to be a key player in providing antivibration and sealing solutions.

Click on the map to join the company on Google Map!